Point Cloud data is often associated with land survey and architectural designs, however, in many modern automation scenarios, Point Cloud data is indispensable in enabling process optimization, 3D inspection, and dimensional monitoring. Industries such as forestry/timber, food processing, or metal handling rely on 3D laser scanners to automate labor-intensive tasks. These 3D laser scanners are high-speed and high-definition to ensure the data is an accurate representation of the target objects. In general, the raw data from a machine vision system is passed downstream to be further processed by software algorithms.

To find out how 3D laser scanners work or the working principle of 3D laser scanners, read about it here.

A quick guide to commonly asked questions on 3D Point Cloud for Industrial Automation

Question 1. What is a Point Cloud? What is Point Cloud representation?

One or more points make up a point cloud and can be used to represent the 3D characteristics of objects, both big and small. From kilometers to nanometers, the units are arbitrary and application-dependent.

When viewed visually via software, a point cloud may look complex or complicated, but the data’s underlying representation is quite simple – a list – where each row identifies the 3 coordinates for each point.

The point cloud is to the 3D scanner what the image is to the camera. Understanding what a point cloud is and how it is structured is fundamental to working with 3D scan data.

Question 2. How is a Point Cloud captured? What are the different modes to generate Point Cloud data?

When capturing a point cloud, there are many different methods. Still, there are three primary modes: single-point capture, profile capture, and complete area capture.

Single Point captures include all methods that capture only a single point of data at any given time, such as range sensors and some types of LIDAR sensors.

Profile Capture includes all methods that capture a single profile of an object at any given time, such as sheet-of-light scanners and linear-coded light scanners. Profile captures include an extra dimension of data where each scan captures a profile of data in space that could be completely represented with just a 2D coordinate system.

Finally, Area Captures return a complete set of 3D data for whatever is in view of the scanning device. Area captures include all methods that take a complete 3D snapshot of a scene, such as indirect time of flight, 2D coded light scanners and sequential pattern encodings.

Question 3. How to 3D Scan a Large Object? How to Combine Multiple Point Clouds Together?

In order to generate a complete point cloud, it is often necessary to combine scans taken at different times, or scans from multiple sensors.

This is known as point cloud stitching.

A good example of this is when scanning around a large moving object. It is desirable to use multiple sensors to be able to see all the way around the object. It is also desirable to use a profile scanner to take advantage of the speed and simplicity of this type of scanning when the object has a known motion.

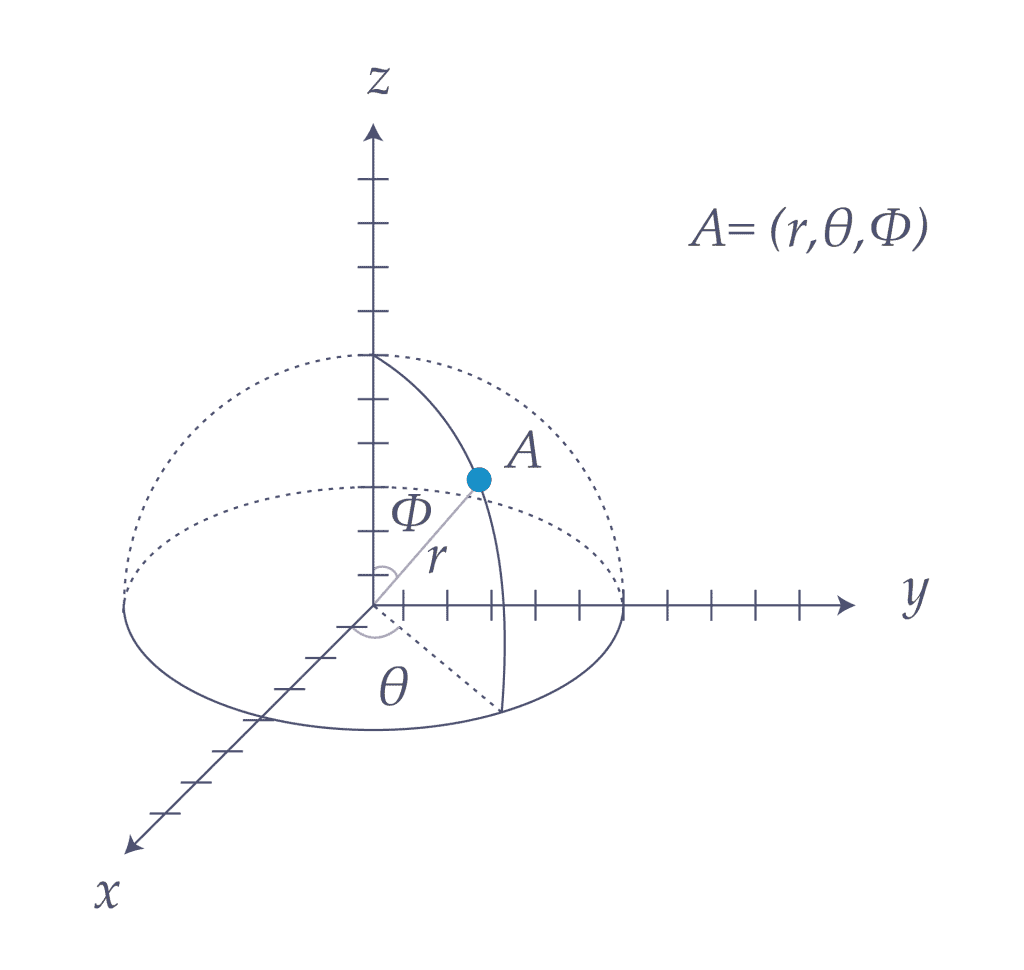

To create one common point cloud, it is necessary to reference each scan both spatially and temporally to a common coordinate system. The Cartesian XYZ coordinate system is most common, but cylindrical, spherical, or any other coordinate system that can define a location in 3D space could be used.

There are methods for referencing multiple point clouds together by identifying common features among the different data sets and running an optimization algorithm. But in online industrial applications, it is most common that the scanner or scanners are set up and calibrated to the system in advance so that everything is referenced to a single base coordinate system. This is to minimize computation lag and to have a known truth of how the data is being represented for subsequent processing tasks.

Question 4. What are some common Point Cloud data augmentation techniques?

In addition to 3D spatial information, point clouds can be augmented with additional data.

Depending on the scanning method and the data available, characteristics such as reflectance, RGB color, surface normal direction, and others can be attached to each point. With this extra data, downstream processing tasks can take advantage of features that may not be visible in just the 3D surface structure of an object alone.

Recommended for you

Capturing 3D data with Geometric Measurement Techniques

Learn about the many techniques 3D data can be captured and the pros and cons of each method.

Point Cloud and How to Digitally Transform Your Manufacturing Capacity

Point Cloud enables machine vision systems and helps manufacturers digitize precious data.

Vision-guided Robotics – Tracking and Tracing Steel Billets

A critical process in metal handling sees a significant upgrade when machine vision is integrated.